Cooling Tower replacement PARTS

We offer a full line of replacement parts for any and all makes or models of cooling towers. These parts can be purchased at the best prices in the industry. Because Cooling LLC is an OEM manufacturer we receive volume and OEM discounts and, in turn, pass those savings on to our customers.

FILLS

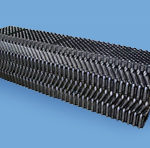

Cross Fluted

CF1200MA Cross Fluted Film Fill Media

CF1200MA Cross Fluted Film Fill Media

AccuPac® Cross Fluted Fills improve water distribution by splitting the water stream as it descends through the fill pack. The CF1200 MA splits the water stream 10 times in a 11.8” (300 mm) vertical path. High thermal performance (high KaV/L) and low pressure drop are simultaneously achieved through engineered flute/microstructure design and the highest manufacturing standards.

CF1900 Cross Fluted Film Fill Media

AccuPac® Cross Fluted Fills improve water distribution by splitting the water stream as it descends through the fill pack. The CF1900 splits the water stream 8 times in a 12” (305 mm) vertical path. High thermal performance (high KaV/L) and low pressure drop are simultaneously achieved through engineered flute/microstructure design and the highest manufacturing standards.

CF1900MA Cross Fluted Film Fill Media

CF1900MA Cross Fluted Film Fill Media

AccuPac® Cross Fluted Fills improve water distribution by splitting the water stream as it descends through the fill pack. The CF1900 MA splits the water stream 8 times in a 12” (305 mm) vertical path. High thermal performance (high KaV/L) and low pressure drop are simultaneously achieved through engineered flute/microstructure design and the highest manufacturing standards.

FS3000 Cross Fluted Film Fill Media

AccuPac® Cross Fluted Fills improve water distribution by splitting the water stream as it descends through the fill pack. The CF3000 splits the water stream 5 times in a 12” (305 mm) vertical path. High thermal performance (high KaV/L) and low pressure drop are simultaneously achieved through engineered flute/microstructure design and the highest manufacturing standards.

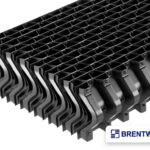

XF12560 Cross Fluted Film Fill Media

XF12560 Cross Fluted Film Fill Media

Brentwood's XF12560/15 is a uniquely designed product for installation in package crossflow towers. This fill has cross corrugated sheets with a built-in internal slant. The sheets have alternating flute angles of 45° and 15°. This allows the fill to be installed vertically without an external slant. The XF12560/15 provides for a simple installation that saves space in the tower which means savings for both assembly and material costs. The XF12560/15 is particularly suited for single flow crossflow towers with fans mounted in a vertical plane.

Offset Vertical

OF21MA Offset Vertical Film Fill Media

OF21MA Offset Vertical Film Fill Media

AccuPac® Offset Vertical Fill combines the low-fouling characteristics of vertical flow with the enhanced water distribution of our cross- fluted designs. The OF21MA’s high KaV/L thermal performance and low pressure drop are similar to the CF1900/CF1900MA design, but with lower potential for fouling.

Vertical Flow

VF19 PLUS Vertical Flow Film Fill Media

VF19 PLUS Vertical Flow Film Fill Media

AccuPac® Vertical Flow Fills feature vertical flow channels with large openings that produce the higher water velocities necessary to create an anti-fouling environment in the fill. In the VF19 PLUS we’ve added an engineered micro-structure to the flutes to improve water distribution and thermal mixing.

VF3800 Vertical Flow Film Fill Media

VF3800 Vertical Flow Film Fill Media

AccuPac® Vertical Flow Fills feature vertical flow channels with large openings that produce the higher water velocities necessary to create an anti-fouling environment in the fill. The VF3800 vertical flow film media gets the job done.

Herringbone

XF75 Cross Flow Herringbone Film Fill Media

XF75 Cross Flow Herringbone Film Fill Media

AccuPac® Cross Flow Herringbone Fill uses a “herringbone” surface design engineered to distribute water evenly over the entire fill area for high thermal performance. Herringbone fills with integrated Inlet Louvers (XF75 IL) and Drift Eliminators (XF75 ID)

High-performance, crossflow media system.

XF75IL Cross Flow Herringbone Film Fill Media with Integrated Inlet Louver

XF75IL Cross Flow Herringbone Film Fill Media with Integrated Inlet Louver

AccuPac® Cross Flow Herringbone Inlet Louver Fills combine an inlet louver with the high thermal performance of the XF75 herringbone cross flow fill pack. The XF75IL Cross Flow Herringbone Film Fill Media with Integrated Inlet Louver gets the job done.

XF75ID Cross Flow Herringbone Film Fill Media with Integrated Drift Eliminator

XF75ID Cross Flow Herringbone Film Fill Media with Integrated Drift Eliminator

AccuPac® Cross Flow Herringbone Drift Eliminator Fills combine a drift eliminator with the high thermal performance of the XF75ID herringbone cross flow fill pack. The XF75ID Cross Flow Herringbone Film Fill Media with Integrated Inlet Louver gets the job done.

Splash Fill

KELLY BAR Splash Fill Media

KELLY BAR Splash Fill Media

Kelly Bar Splash Fill Media, a well-known splash fill profile with a proven performance track record, is now precision-manufactured by Brentwood. Named after Neil Kelly, the man responsible for significant contributions in the field of crossflow wet cooling technology and publisher of the "Kelly Handbook of Crossflow Cooling Tower Performance", this classic design maximizes practicality and can be oriented either parallel or perpendicular to airflow and in any standard fill arrangement, depending on thermal requirements.

V BAR Splash Fill Media

V BAR Splash Fill Media

Brentwood V Bar Splash Fill Media, field-proven for over 30 years, is a durable, high-performance PVC replacement for wooden splash fills and OEM Splash Bars. The Brentwood V Bar Splash Fill Media gets the job done.

PI BAR Splash Fill Media

PI BAR Splash Fill Media

Brentwood Pi Bar Splash Fill Media is designed for extra-dirty water applications where a 2" (51mm) wide bar is desired. The domed top and sloping legs help shed accumulation of solids while improving the splash effect. The Brentwood Pi Bar Splash Fill Media gets the job done.

LATH Splash Fill Media

LATH Splash Fill Media

Brentwood Lath Splash Fill Media is a lightweight, strong PVC replacement for wooden lath in crossflow or counterflow cooling towers. Available UV-stabilized PVC Brentwood Lath is more resistant to weather, chemicals, and biological attack. The self extinguishing properties of PVC means risk of fire is minimal The Brentwood Lath Wire Hanging System is available for secure, effective installation of Lath Splash Fill Media.

TurboSplash PAC Splash Fill Media

TurboSplash PAC Splash Fill Media

Brentwood TurboSplash PACs are splash media assemblies with hinged panels that can be installed in horizontal and vertical arrays for high thermal performance in counterflow and crossflow cooling tower applications. Each unit can be accordion-folded into a compact bundle for efficient, cost-effective storage and shipping and then unfolded in the tower for easy installation.

Gull Wing Fill Slats

Gull Wing Fill Slats

Gull Wing Fill, available in 4-inch or 6-inch widths, is our latest and most efficient fill slat offering. The unique design of the Gull Wing Fill effectively addresses two key concepts clearly lacking in the majority of competitive fill slats: span and water bypass. Span is assured with full bearing surface contact between the slat and hanger and a center rib stiffener for increased strength. A unique retainer notch placed at regular intervals creates a space for the hanger grid while providing a full eighth-inch overhang per side to virtually eliminate water bypass. Thermally, the Gull Wing Fill is a superior offering when compared to other splash fill bars currently on the market. In fact, the author of the MRL Rating Software, a rating program used by the majority of cooling tower companies, states, "Gull Wing Fill installations have never rated short when using MRL original data and comparing the thermal projections to that of the actual field test results". Gull Wing Fill, when used in conjunction with Shepherd Fill Slat Hangers, is offered with a 10-year warranty!

Opti-Bar Fill

OPTI - BAR Features:

- Open Mesh Design – OPTI - BAR’s open mesh design perfects the mixing of water drops and air while eliminating water channeling Two splash layers in each bar create more tiny water droplets and the ultimate cold water temperature.

- Durable HDPE Construction – OPTI - BAR’s High Density Polyethylene material and rectangular mesh is stronger than PVC splash bars. HDPE does not become brittle in freezing temperatures, resists chemical and biological attack and operates up to 145°F.

- Low Flame Spread – HDPE formulation has a flame spread rate of 25 or less per ASTM E84.

- No Wear Pads or Retainer Clips – OPTI - BAR’s HDPE material properties eliminate the need for separate wear pads and retainer clips that can find their way into the circulating water system.

OPTI - BAR Benefits:

- Colder Water – Whether building a new tower or upgrading an old tower that has outdated PVC fill bars, OPTI - BAR produces the coldest water available from any splash bar fill.

- Increased Efficiency – Colder return water means increased capacity. Less airflow resistance of open mesh bar reduces the cost of parasitic fan power consumption.

- Resistance to Temperature Spikes – When the unexpected happens, OPTI - BAR resists temperature upsets that make PVC bars go limp.

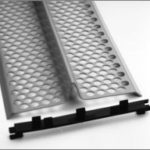

Hanger Grids & Brackets

Time tested Shepherd Fill Slat Hangers deliver longer tower life and virtually eliminate fill support failure. Shepherd Fill Slat Hangers are precision welded wire with uniform grid size and superior corrosion resistance. Hangers are available in galvanized, PVC coated or stainless steel mesh. Standard grids in a variety of gauges, straight or racked, are available and in stock. Custom grids may be made to order. Shepherd's unique 3" steel spiral binders may be used to quick connect length drops. As with our hangers, binders are available galvanized, PVC coated or stainless steel. Hanger Brackets, manufactured from high quality, corrosion resistant polypropylene, support Shepherd Fill Slat Hangers making installation faster, easier and more efficient.

Fill Slats & Retainer Clips

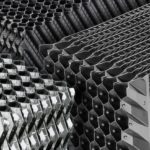

Cellular Fill

Sheperd produces a complete line of high quality extruded PVC cooling tower fill slats designed for parrallel and perpindicular installations. Rigid and straong. Shepard fill slats are engineered for maximum efficiency with minimum power requirements. The most efficient heat transfer method for counterflow cooling towers is accomplished via cross corrugated film-type media or fill. This is manufactured from high quality, virtually unbreakable polypropylene secure the Shepherd Gull Wing or V-Bar Splash Fill Shepherd Company currently offers two such media, CES-190 and CES-120 (see specifications below for details). CES sheets conform to the commercial standard ASTM D1784:12454B. Our sheets can be shipped nested for your assembly or shipped assembled from any one of our four assembly locations. Assembled CES packs can be cut to fit snugly around framework while still maintaining its rigidity. A perpendicular stacking installation provides break-up points for silt allowing continual flushing of contaminates. The individual stacks allow easy removal for cleaning or replacement if required. CES Film Fill Packs significantly increases cooling tower efficiency as its expansive surface area accelerates cooling in a thin film of water. This increased efficiency translates to reduced pump head and horsepower requirements.

VE-210 Film Pack Fill

VE-210 Film Pack Fill

Shepherd VE-210 film fill system delivers superior performance with reduced fouling. The vertical entrance / vertical exit media design promotes free flow of debris and biological growth while the cross-corrugations maximize surface area and create turbulence to ensure efficient heat transfer. Packs are assembled from corrugated sheets bonded with an environmentally friendly adhesive at dedicated glue points. This bonding method produces the strongest packs available, assuring both ease of handling through the rigorous installation process and effective performance during operation.

The VE-210 is a low-fouling, thermally efficient, durable media perfect for heavy industrial applications including power plants, refineries, petrochemical plants and pulp/paper production. Additionally, versatile VE-210 is appropriate in light to medium industries such as the HVAC market. As with all Shepherd Cooling Tower Components, VE-210 is designed for retrofits and new construction alike; VE-210 can boost performance in towers old and new, regardless of manufacturer.

- Maintenance Cost Savings – OPTI - BAR’s superior strength minimizes winter ice damage. And, no retainer clips mean less cleanup of debris in strainers.

WATER DISTRIBUTION COMPONENTS

Nozzles

Dek-Spray® Nozzles

Dek-Spray® Nozzles

The Brentwood Dek-Spray Nozzle is actually a lightweight, corrosion-resistant, cost-effective, easy-to-install, versatile nozzle system that offers multiple turbulator and orifice options to optimize water distribution and cooling efficiency in counterflow cooling towers.

Target Nozzles for Cross Flow Towers

Target Nozzles for Cross Flow Towers

Shepherd Target Nozzles provide better water distribution at various head and flow rates, are longer lasting and fit standard 1-5/8" deck holes. They are engineered to produce maximum uniformity of water dispersion with the minimum vertical distance by deflecting water flow vertically and laterally, offering more available tower height for fill slat installation.

Target Nozzle Screens (not shown) are designed to prevent clogging of the orifice. Manufactured from durable, polypropylene, each injection molded part measures 6" in height by approximately 2.5" in diameter and has a uniform mesh of 1/2" x 1/2". The screens snap directly onto optional tabs on the top of a Shepherd Target Nozzle. The Nozzle Screen Assembly offers an economical solution for protecting expensive components downstream from the cooling tower.

Crown Nozzles for Cross Flow Towers

Crown Nozzles for Cross Flow Towers

Shepherd Crown Nozzles provide better water distribution at various head and flow rates, are longer lasting and fit standard 1-3/4" deck holes. Crown Nozzles, available in standard 3" x 4.6" length size, eliminate the vortex spiral of water thus creating the same consistent uniform diffusion pattern at any height of head. The improved diffusion plate design is superior in the distribution of water allowing uniform spread in all directions. Lock-in tabs on the telescoping nozzles body allow for ease of installation into the hot water deck. The tabs lock

Square Pattern (SP) Nozzles for Counter Flow Towers

SP Nozzles maximize water contact to the heat transfer media (fill). Water exits the nozzle in a uniform spray of fluidized water particles in a large surface to volume ratio. Unlike nozzles that disperse water in a circular pattern, the SP Nozzles is configured to mirror the footprint of straight sided industrial cooling towers, assuring coverage for all areas of the fill while significantly reducing water shedding on the side, partition and end walls. With proper installation, the SP Nozzles are pitched to produce overlapping individual sprays from adjacent nozzles. This design, in concert with the engineered spray of uniformly sized water droplets, achieves ideal distribution over the fill and in turn, assures maximum heat transfer within the fill system itself.

Quick Change Orifice (QCO) Nozzles for Counter Flow Towers

Shepherd QCO Nozzles offer a uniquely designed diffusion plate which provides the uniform water dispersion in all directions necessary to achieve the best results in a counter flow tower design. This even flow prevents streaming as the water exits the nozzle and ensures sufficient contact with fill media. The 1.5" NPT nozzles feature a large diameter opening to preclude the build-up of silt and to allow the passage of cleaning balls. Combining both economy and quality, the Shepherd QCO Nozzle is a superior performer.

DRIFT ELIMINATORS

Cellular

CF80MAx Counterflow Cellular Drift Eliminators

CF80MAx Counterflow Cellular Drift Eliminators

CF80MAx Counterflow Cellular Drift Eliminators are specifically-designed to achieve maximum drift removal. Unlike other drift eliminators designed for both counterflow and crossflow towers, Brentwood's counterflow eliminators have significantly lower pressure drop than dual-purpose eliminators.

The modules are constructed of a series of sinusoidal-shaped corrugated CTI STD-136 PVC sheets that are mechanically assembled to mating sinusoidal structural waves to form closed cells. These cells force the drift droplets carried in the leaving airstream to make three distinct changes in direction. This disruption of the air flow creates centrifugal forces on the drift droplets, forcing them to be captured by inertial impaction and direct interception with the module walls and thereby removed from the airstream.

XF80MAx Crossflow Cellular Drift Eliminators

XF80MAx Crossflow Cellular Drift Eliminators

XF80MAx Crossflow Cellular Drift Eliminators provide the best available drift removal efficiency on the market today. The upward flow path, steep water drainage angle, and “tuned venturi section” make this the ideal product for factory-built crossflow towers.

Brentwood ACCU-PAC Cellular Drift Eliminator modules are constructed of a series of sinusoidal-shaped, corrugated, CTI STD-136, PVC sheets that are mechanically assembled to mating sinusoidal structural waves to form closed cells. These cells force the drift droplets carried in the airstream to make three distinct changes in direction. This diversion of the air flow creates centrifugal forces on the drift droplets, forcing them to be captured by inertial impaction with the cell walls and thereby removing the droplets from the airstream.

CF150MAx Counterflow Cellular Drift Eliminators

CF150MAx Counterflow Cellular Drift Eliminators

CF150MAx Counterflow Cellular Drift Eliminators are specifically-designed to achieve maximum drift removal efficiency in counterflow tower applications while keeping pressure drop significantly lower than in cellular drift eliminators designed for crossflow cooling towers.

The modules are constructed of a series of sinusoidal-shaped corrugated CTI STD-136 PVC sheets that are mechanically assembled to mating sinusoidal structural waves to form closed cells. These cells force the drift droplets carried in the leaving airstream to make three distinct changes in direction. This disruption of the air flow creates centrifugal forces on the drift droplets, forcing them to be captured by inertial impaction and direct interception with the module walls and thereby removed from the airstream.

XF150MAx Crossflow Cellular Drift Eliminators

XF150MAx Crossflow Cellular Drift Eliminators

XF150MAx Crossflow Cellular Drift Eliminators are specifically-designed to achieve maximum drift removal efficiency in crossflow tower applications by providing an upward flow path and discharge angle of 40-55° from horizontal (depending on installation angle) and molded-in drainage channels that direct the collected drift back to the wet section of the tower even when impacted by water spray.

The modules are constructed of a series of sinusoidal-shaped corrugated CTI STD-136 PVC sheets that are mechanically assembled to mating sinusoidal structural waves to form closed cells. These cells force the drift droplets carried in the leaving airstream to make three distinct changes in direction. This disruption of the air flow creates centrifugal forces on the drift droplets, forcing them to be captured by inertial impaction and direct interception with the module walls and thereby removed from the airstream.

The blades are held together with one-piece end caps, forming an assembled module that is lightweight but strong enough to span up to 6 ft. (1.8 m) between supports, saving material & labor costs and reducing air blockage.

BLADE

DE-080 Blade Drift Eliminators

DE-080 Blade Drift Eliminators

DE-080 Blade Drift Eliminator Modules use a tightly-spaced series of sinusoidal-shaped, PVC (or HPVC) blades that force the leaving air

to make 3 distinct changes of direction, resulting in maximum drift droplet removal. But this performance does not come at the expense of fan energy, as the engineered flow through the DE-080 achieves very low pressure drop. The blades are held together with one-piece end caps, forming an assembled module that is lightweight but strong enough to span up to 6 ft. (1.8 m) between supports, saving material & labor costs and reducing air blockage.

DE-097 Blade Drift Eliminators

DE-097 Blade Drift Eliminators

DE-097 Blade Drift Eliminators are specifically-designed for use in forced draft cooling towers. Like the DE-080 and DE-120, these drift eliminators use a series of sinusoidal-shaped PVC (or HPVC) blades to achieve excellent drift droplet removal by forcing the leaving air to

make 3 distinct changes of direction. Where this product differs is the additional deflector designed into the discharge edge of each blade that increases the velocity of the leaving airstream and directs it away from the intake fans.

DE-120 Blade Drift Eliminators

DE-120 Blade Drift Eliminators

DE-120 Blade Drift Eliminator Modules use a series of sinusoidal-shaped PVC (or HPVC) blades to achieve excellent drift droplet removal by forcing the leaving air to make 3 distinct changes of direction. The more open 1.200" (35 mm) blade spacing allows for high performance at low pressure drop and cost. (This is our most affordable drift eliminator.)

The blades are held together with one-piece end caps, forming an assembled module that is lightweight but strong enough to span up to 6 ft. (1.8 m) between supports, saving material & labor costs and reducing air blockage.

SDRU Drift Reduction Units

Designed for both crossflow and counterflow applications, CES-DRUs (CE Shepherd Drift Reduction Units) in modules measure 12-1/2" wide x 5-1/4" deep. Maximum available length is 10'. The modules nest together tongue-and-groove fashion for increased protection from drift loss. CES-DRU may also be provided in a non-nesting form (DRU 1.5N). When water enters the plenum area, droplets are caught in the exit air stream. Propelled at high velocity, these droplets erode rotating fan blades and drive shafts, gear boxes, mechanical supports and other stationary equipment all located in the plenum chamber. As it escapes the tower, this drift is a likely cause of damage to any neighboring equipment, parking lots, roads and the like. Excess drift also increases make-up requirements, a potentially serious problem given today's emphasis on water conservation. The CES-DRU1.5 is an engineered solution for the removal of entrained water droplets within the exit air stream. Shepherd Drift Reduction Units provide a low pressure drop for increased air flow, reduced maintenance and prolonged operating life.

SDRU-XF Drift Reduction Units

Designed specifically for crossflow applications, Shepherd Drift Reduction Unit SDRU_XF is manufactured in modules 12-1/2" wide x 5-1/2" deep. The modules nest together tongue-and-groove fashion for increased protection from drift loss while the discharge angle and drainage slots ensure trapped drift is returned to the "wet side" of the cooling tower.

FANS

TufLite Fans

Tuf-Lite® are high performance, durable, and efficient fans used in air-cooled heat exchangers, cooling towers, and air-cooled steam condensers (ACCs). Tuf-Lite® can be used as an OEM product or as a performance upgrade to improve reliability, air-flow, cooling performance, and energy efficiency. Tuf-Lite® are hand-laid-up molded fan blades with either epoxy resin or a proprietary vinyl ester resin that is specifically formulated for Hudson. Each blade has a different fiberglass configuration that is as a result of 60+ years of know-how and continuous improvement and innovation. Additionally, Tuf-Lite II® and Tuf-Lite III® include a UV protective coating and our proprietary Tuf-Edge® embedded leading edge protection. Due to this design, Tuf-Lite® are the most reliable fans in the world.

- Tuf-Lite® will outperform its competition and ensure that you are receiving the necessary performance and reliability that you demand from your cooling tower fan.

- Tuf-Lite® is designed to withstand the most corrosive and demanding environments in the cooling tower industry.

- Tuf-Lite® is the most requested axial flow fan in the field erected cooling tower market

Tuf-Lite I

- The original Tuf-Lite, first generation

- Created in the 1950s and still going

- Single piece, light weight construction

- Constructed with an epoxy resin

- Available in 5'-40' diameters

Tuf-Lite II & III

- Tuf-Lite II® was created in 1984 and Tuf-Lite III® in 2004. Both blade families are manufactured in Texas.

- Tuf-Lite II® and Tuf-Lite III® have their own air-foil designs which provide different performance characteristics. Contact our engineers to determine the best option for your needs.

- Tuf-Lite II® is a two piece fan blade and Tuf-Lite III® is a one piece fan blade.

- Both types are constructed of vinyl ester resin developed specifically for Hudson.

- Both incorporate Hudson’s patent Tuf-Edge® leading edge protection and stainless steel and neoprene leading edge protections are available upon request.

- Both include exterior UV protective coatings.

- Tuf-Lite II® is available from 6’ to 40’ in diameter.

- Tuf-Lite III® is available from 11’ to 10 meter in diameter. 6’-10’ diameters will be available in the Fall of 2016.

Tuf-Lite III KW

Tuf-Lite III KW® is in a class of its own. The KW is the most versatile and highest performing fan in its class. The KW is a wide chord fan available from 11’-20’ in diameter. Due to its innovative design, it can be used to provide more air flow that is unmatched by any other fan, can be used for lower noise applications, is energy efficient, and is as reliable as all Hudson fans. The KW can be used in any 11’-20’ application and is most commonly used for air-cooled heat exchangers, field erected cooling towers, and package cooling towers.

DRIVESHAFTS

Addax Couplings

These advanced composite coupling systems have been installed around the world and are utilized for a number of applications. The patented flex element was developed to withstand harsh conditions and high misalignment problems found in cooling towers. The advanced composite full floating center section weighs less than 25% of a comparable steel spacer. With almost twice the critical speed of metals and up to an 80% reduction in overhung bearing loads, these composite couplings reduce vibration and extend driven equipment

bearing life.

Form flex couplings

Form-Flex® couplings transmit torque while compensating for angular, parallel and axial misalignment between two connected shafts. Flexible disc couplings minimize the misalignment forces on the connected equipment.

Rexnord Addax Drive Shaft:

These couplings are made with lightweight, advanced composite material to increase critical speed, reduce vibration, and extend bearing life. As a result, they can reduce overhung bearing loads up to 80% compared to alternative metal couplings. Rexnord Addax Composite Couplings are designed to your specifications and made to order.

Features & Benefits:

Corrosion-resistant parts lower cost of ownership and extend service life.

Can span from motor to gearbox without intermediate support bearings.

Up to 5.06 inches (130 mm) bore capacity.

Up to 36,200 in-lb (4,090 Nm) torque capacity.

Up to 500 hp.

Custom spacer lengths up to 275 inches (6,985 mm).

13 sizes available.

Patented unitized flex elements eliminate fretting.

Ships in less than 24 hours if required.

GEARS

Cooling Towers, LLC. offers a wide variety of Cooling Tower Gear Boxes. Whether it’s a top of the line name brand you are looking for, a surplus or a re-built, we can supply it for you! We offer both Amarillo and Marley Gearboxes.

Classic Single Reduction Right Angle

Gearboxes incorporating one reduction ranging from ratios of 2:1 to 9.5:1. Power ranges from 7 HP (5.2 kW) up to 134 HP (100 kW).

Classic Double Reduction Right Angle

Reduction ratios range from 7.5:1 to over 20:1. Power ratings start at 60 HP (45 kW) and exceed 500 HP (375 kW).

VALVES

The distribution valve is a direct replacement valve for all existing crossflow Cooling Tower distribution valves. The SS Series valve is manufactured entirely from 304L or 316L stainless steel and UHMW-PE plastic, eliminating corrosion and maintenance concerns. In addition, the valve features a 30% larger discharge area and 40% reduction in weight compared to conventional distribution valves making it the new industry standard. The valve has been designed with a superior internal guide system that supports the stem and disc throughout its' full length of travel. The internal "tracking system" provides the support necessary to allow the valve to be used for balancing water flow. Conventional distribution valves wear excessively due to the movement or "chatter" of the stem and disc as they encounter the turbulence of the water flow, requiring costly downtime for repairs or replacement. The valve can be utilized to balance the water flow throughout your Cooling Tower, optimizing its' performance. Another advantage of the valve is the combination of a stainless steel stem and UHMW-PE plastic bushing which requires no greasing or maintenance. In addition, the bushing assembly replaces easily from the valve exterior, eliminating costly downtime. Along with the internal guide system which centers the disc and places the disc surface parallel to the seating face, an improved gasket system allows complete and positive shut-off of the water stream without the persistent leaking associated with conventional valves

MOTORS

Our Severe Duty Cooling Tower motor is a low voltage motor that is specifically designed for cooling tower applications in wet and humid environments. Built with a severe duty enclosure and coated with corrosion-resistant epoxy paint, the motor can withstand the most extreme operating conditions. This motor is ideal for industrial cooling tower applications where durability and reliability are essential. Available in ¾ to 75 horsepower (HP), the Cooling Tower motor features severe duty IP56 protection and is designed to operate in 100% humidity. Enclosure options include totally enclosed fan cooled (TEFC) and totally enclosed air over (TEAO) designs for all operating conditions. Additional features include:

- Ingress Protection IP56 for Wet & Humid Environments

- 1800 & 1200 RPM Designs

- 230/460/ or 575 V 3-Phase 60 Hz

- Up to 365T NEMA Frame

- Suitable for Inverter Duty

FAN STACKS

- Wide selection of sizes- 100 different stock profiles with custom molds available.

- Resins available in general purpose or Class I or Class II Fire Retardant formulations.

- Colors available in the standard Mist Gray or optional custom colors.

- Hand laid with layers of woven and mat fabrics to maintain product consistency.

- Mat and woven fabrics are specifically engineered into the total laminate to provide the structural requirements needed to make our fan stacks the finest in the industry.

VIBRATION SWITCHES

The Murphy Explosion-Proof Shock and Vibration Switch VS2EX is a shock sensitive mechanism for shutdown of engine or electric motor powered equipment. This switch uses a magnetic latch to ensure reliable operation. The Murphy Explosion-Proof Shock and Vibration Switch is housed in an explosion-proof enclosure with threaded cover. This enclosure is CSA and UL listed for Class I, Division 1, Groups C & D hazardous locations. In place of the leaf type contacts, 2-SPDT snap-switches are used in this model. Sensitivity is externally adjustable and, when tripped, the VS2EX gives a Tattletale indication on the reset button. It is constructed to meet NEMA 7 specifications.

Ideal for use on engines, pumps, compressors, heat exchangers and pumping units, the VS2 Series can be used anywhere shutdown protection from damaging shock/vibration is desired. Switches are field adjustable to sensitivity required in each application.

PRODUCT FEATURES:

- Explosion-proof

- Designed to Detect Shock/Vibration in 3-Planes of Motion

- Fully Adjustable

- Includes Magnetic Latching Feature

- Manual or Electric Reset

- NEMA 7/IP50

- Snap-switch Contacts

- Tattletale Reset Button

- 2-SPDT Switches (DPDT)

PRODUCT SPECIFICATIONS:

- Part No.: VS2EX

- Case: Base mount, explosion-proof aluminum alloy housing; meets NEMA 7/IP54 specifications; Class I, Division 1, Groups C & D; UL and CSA listed

- Snap-switches: 2-SPDT snap-switches; 5A @ 480 VAC;* 2A resistive, 1A inductive, up to 30 VDC

- Normal Operating Temperature: -40 to 140°F (-40 to 60°C)

- Electrical Contact Rating: 5 A @ 125–480 VAC, 1/2 A @ 125 VDC, 1/4 A @ 250 VDC, 2 A Resistive 30 VDC, 1 A Inductive 30 VDC

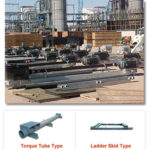

MECHANICAL SUPPORTS

Cooling Towers LLC can provide Hot Dipped Galvanized mechanical supports both Unitized and Torque Tubes of all sizes.

NEED PRICING?

If you have questions regarding specific parts and pricing, please call 281-484-2665, OR FILL OUT THE FORM BELOW.

Thanks for your message! We’ll be in touch soon.

Protect Your Equipment with Cooling Towers LLC'S

Fan Lock - Mechanical Equipment Locking System.

Cooling Towers LLC would be happy to perform a

free, personal demonstration of the Fan Lock.

PROVEN TRACK RECORD

We have a reputation of excellence, reliability and superior customer service. We would like to demonstrate to you that true quality workmanship is second nature to our crews and management team. We look forward to servicing your needs!

USEFUL LINKS

STAY CONNECTED

Join our mailing list for updates

Thanks for signing up!