OUR SERVICES

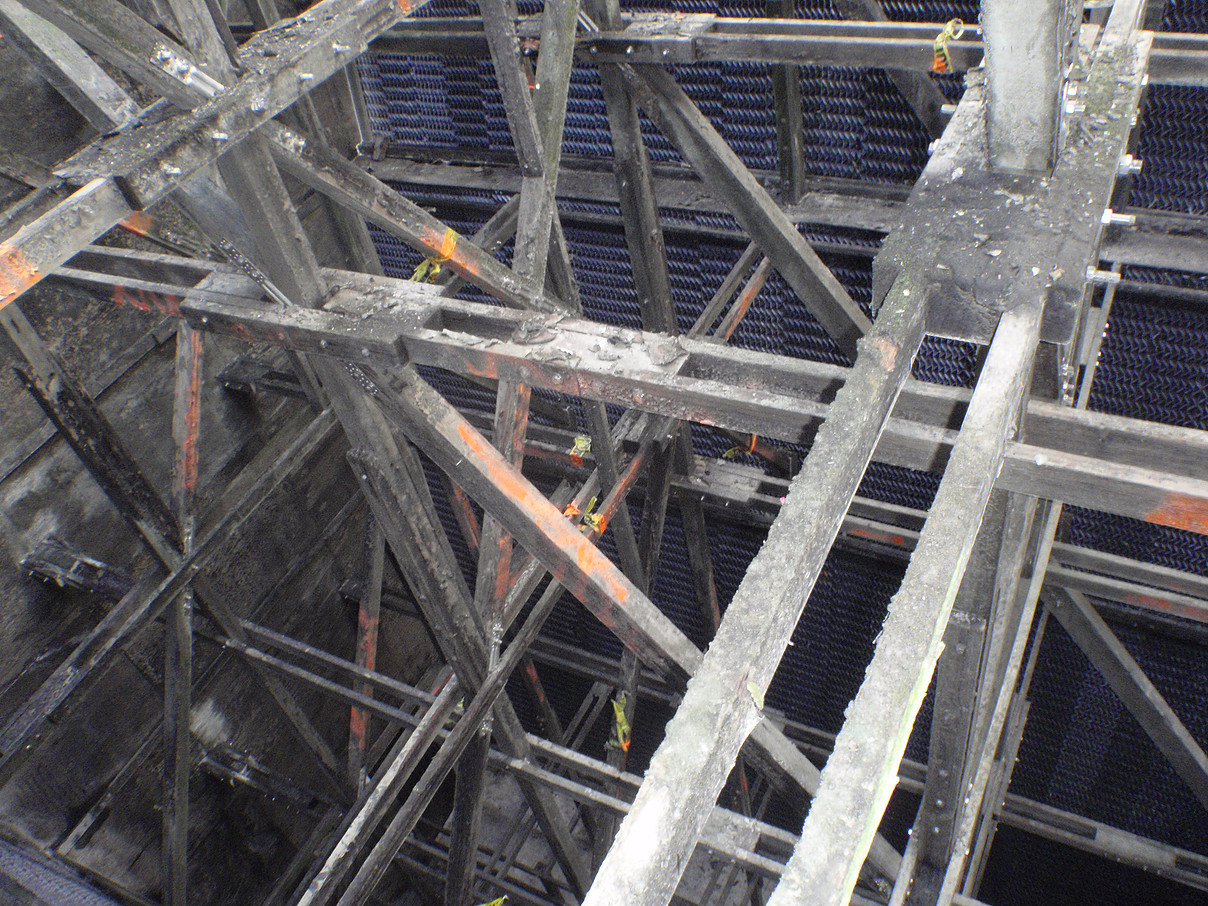

FRP Conversions

Cooling Towers LLC can offer to replace the existing, deteriorating and rotted lumber structure components with new FPR structural shapes. FRP structural shapes are available in shapes that were specifically designed to replace the existing lumber components. The FRP structural shapes are as strong if not stronger than the existing lumber components and unlike treated lumber is resistant to rot and non-corrosive. Typically an FRP conversion is performed in conjunction with an upgrade of the existing internal cooling tower components such as the fill media and drift eliminators. These components must be removed in order to access the cooling tower structure. This is the perfect opportunity to upgrade to new technology that is more efficient and can increase the thermal performance of your tower and increase the overall efficiency of your facility’s processes, while increasing the service life of your cooling tower.

Cooling Tower Inspections

Cooling Towers LLC provides comprehensive and thorough inspections of wood, fiberglass, steel and concrete cooling towers. The strength of structural members in a cooling tower decreases with prolonged exposure to wet/dry atmospheres and treatment/process chemicals. If you are in doubt about the soundness of the structure of your cooling tower then a thorough inspection and a structural analysis may be needed. Cooling tower structures can be damaged by high wind, vibration, biological or chemical attack, seismic event or age. A professional cooling tower inspection ensures that any structural or mechanical difficulties are identified and addressed before they become structural or mechanical disasters.

Inspections Include :

•Safety – OSHA Compliance

•Structural Integrity

•Mechanical Equipment Longevity

•Thermal Efficiency

•External/Internal Components

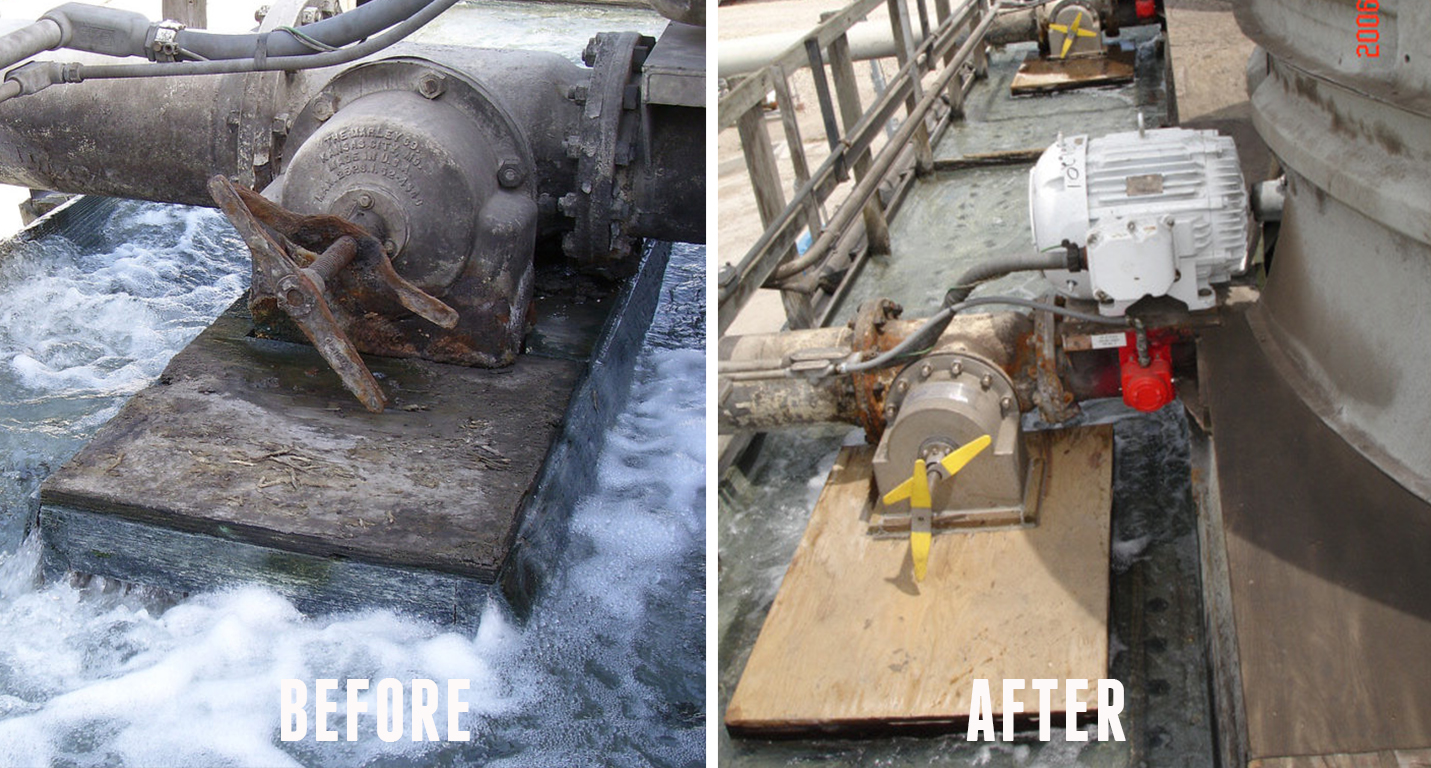

Cooling Tower Repairs

Cooling Towers LLC utilizes the highest quality pressure treated Redwood lumber, Douglas fir lumber, plywood, fiberglass and stainless steel hardware in performing repairs. Use of quality materials along with competent crews and professional installation ensures the structural stability of your cooling tower while greatly extending its service life.

Products such as Amarillo gear reducers, Addax drive shafts and Hudson high efficiency fan assemblies are used by Cooling Towers LLC in performing mechanical repairs. Cooling Towers LLC uses only the highest quality parts to ensure the highest level of performance for our customers.

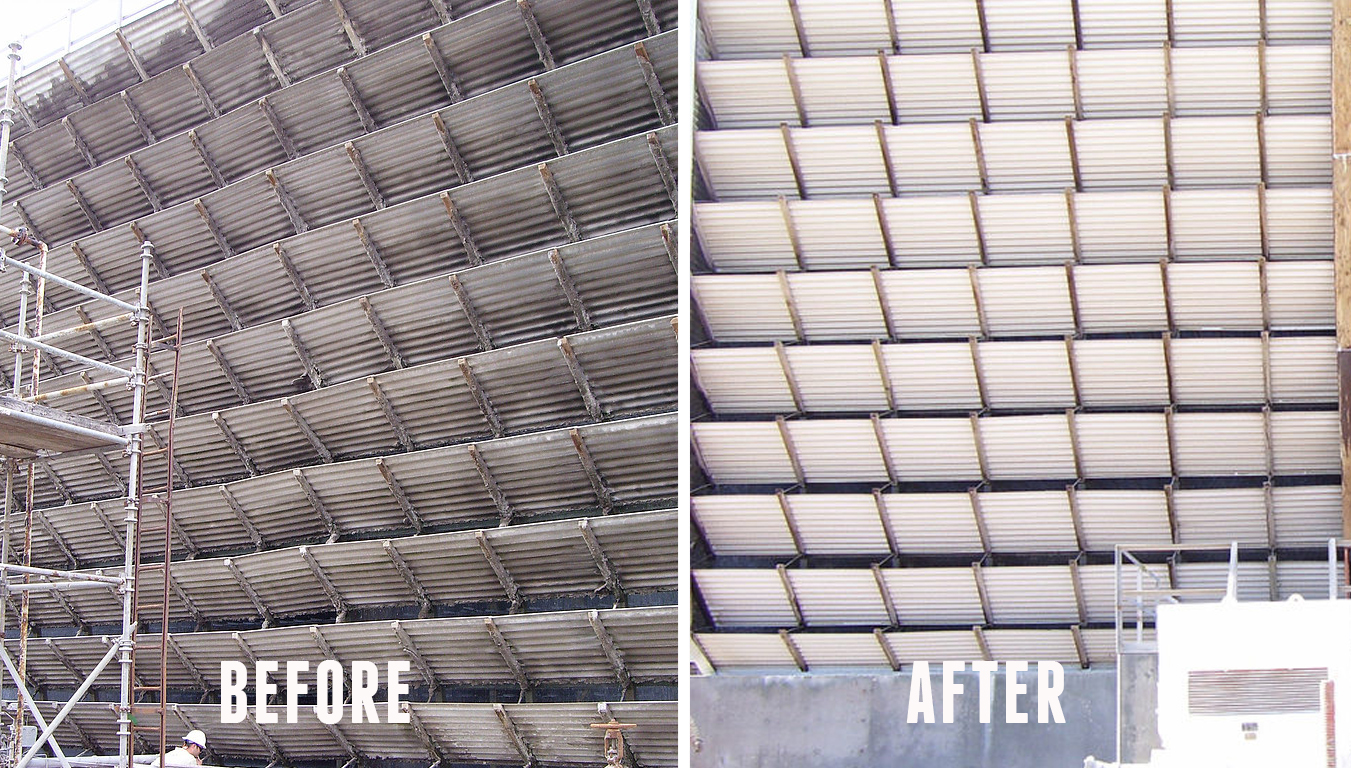

THERMAL COMPONENTS

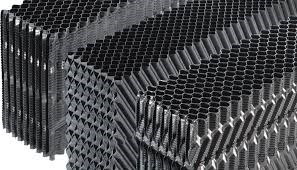

The contact point between air and water is where the heat transfer occurs. This makes the heat transfer media, or "fill" the heart of a cooling tower. Various factors, such as performance requirements and water quality, are taken into consideration when selecting the appropriate replacement fill. The proper drift eliminators can do just that; virtually eliminate drift. This will not improve your tower's performance, but will help prevent costly future repairs due to corrosion of mechanical equipment and its supporting structure.

PREVENTIVE MAINTENANCE

Cooling Towers, LLC recommends performing maintenance on the mechanical equipment of each cooling tower and fin fan cell annually. Cooling Towers, LLC. offers a comprehensive maintenance program that ensures the mechanical components will perform as designed and provide reliable performance. Each mechanical component is carefully inspected, checked for proper performance, alignment and clearances by qualified, experienced Fin Fan technicians. Any issues that are discovered during the execution of the preventive maintenance will be reported immediately. Cooling Towers, LLC. will diagnose the issue and offer the customer options to correct the problem.

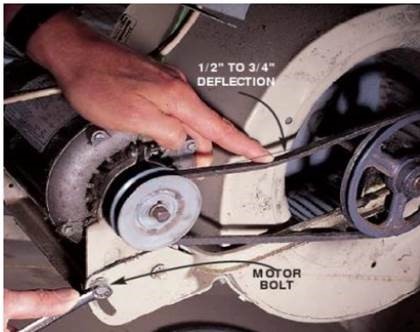

Cooling Towers, LLC offers a full line of replacement parts for all makes or models of fin fans. We will assess the condition of each component and recommend upgrades when needed. Cooling Towers LLC will only recommend the highest quality products to our customers , such as Hudson high efficiency fan’s, Gates belts and sheaves to help maintain the proper speed. These parts can be purchased at the best prices in the industry. Because Cooling Towers, LLC is an OEM manufacturer we receive volume and OEM discounts and, in turn, pass those savings on to our customer’s.

Fin Fan

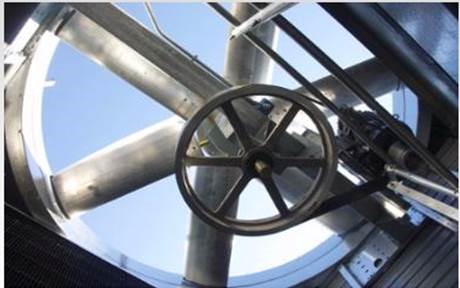

Performing annual preventive maintenance on the mechanical components of a fin fan ensures the longevity of the equipment and optimal performance of the fin fan. Cooling Towers LLC will inspect and service the mechanical equipment components. A report of each mechanical component providing the current status of the components and highlighting any current or possible future issue will be provided to the customer. We inspect the fan blades for damage, wear and pitting. We check the torque on the fan blades connecting hardware. We set the fan blade pitch to draw optimum airflow, and also set the fan blade tracking to within the manufacturer's tolerances. Cooling Towers LLC will also inspect the fan hub for corrosion and loose hardware. On the gear reducers, we will inspect the oil lines and vents, as well as check the pinion and fan shaft for backlash and radial movement. We will rotate the shafts and check for abnormal noises or restrictions. The gear oil will be replaced with new EP Compound 220 gear oil, provided by Cooling Towers LLC. Old oil will be disposed of by others. Cooling Towers LLC will inspect the driveshaft's couplings for excess wear and damage. We will also check the grommets or shim packs for distortion. We will align and record driveshaft settings at the motor and gear couplings. Cooling Towers LLC, will also check the motor shaft rotation for smooth operation or radial movement. We will grease the motor bearings, and check all hold down bolts for proper torque.

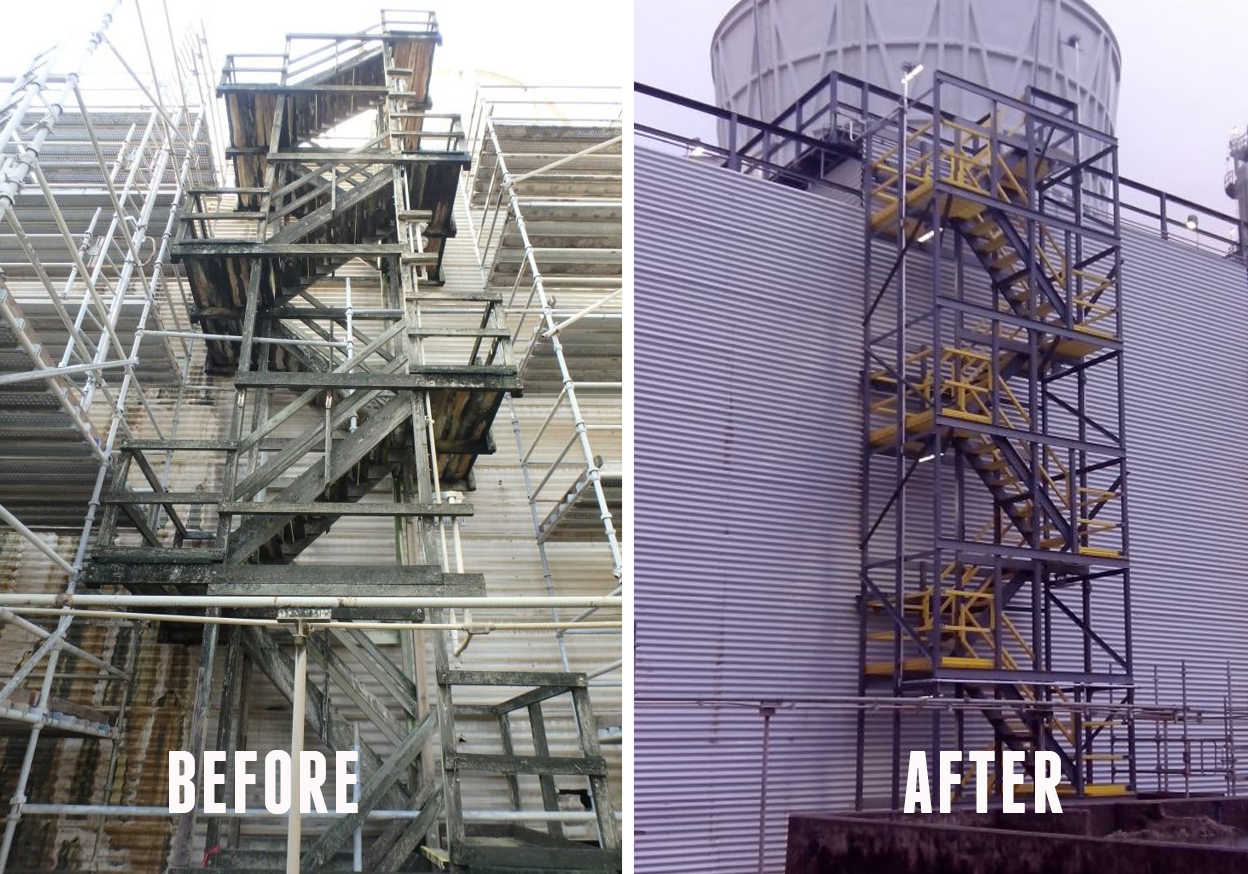

Mechanical Equipment Access Walkways

Mechanical equipment access walkways are a very valuable accessory to any cooling tower. Mechanical equipment access walkways offer consistent, safe access to the mechanical equipment components. The walkways consist of FRP structural shapes and grating panels and resistant to corrosion and rot. The walkways are equipped with handrails, knee-rails and toe boards. The walkways eliminate the need to install scaffolding to access the mechanical components. This significantly simplifies periodic maintenance on the mechanical components and saves money over the life of the tower.

PROVEN TRACK RECORD

We have a reputation of excellence, reliability and superior customer service. We would like to demonstrate to you that true quality workmanship is second nature to our crews and management team. We look forward to servicing your needs!

USEFUL LINKS

STAY CONNECTED

Join our mailing list for updates